You are here: Planning the Model > Steps for Doing Simulation > Step 1: Planning the Study > Preparing a Simulation Specification

With clearly defined objectives and constraints, the simulation requirements can be specified. Defining a specification for the simulation is essential to projecting the time and cost needed to complete the study. It also guides the study and helps set expectations by clarifying to others exactly what the simulation will include or exclude. A specification is especially important if the simulation is being performed by an outside consultant so that you will know exactly what you are getting for your money. Aspects of the simulation project to be contained in the specification should include the following:

Each of these specification criteria will be discussed in the following pages.

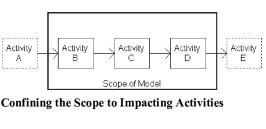

Scope The scope refers to the breadth of the model or how much of the system the model will encompass. Determining the scope of the model should be based on how much bearing or impact a particular activity has on achieving the objectives of the simulation. A common tendency is to model the entire system, even when the problem area and all relevant variables are actually isolated within a smaller subsystem. If, for example, the objective is to find the number of operators required to meet a required production level for a machining cell, it is probably not necessary to model what happens to parts after leaving the cell.

The following figure illustrates how the scope of the model should be confined to only those activities whose interactions have a direct bearing on the problem being studied. Upstream and downstream activities that do not impact the performance measure of interest should be omitted from the model. In the following figure, since the output rate from activity A is predictable, it can be modeled as simply an arrival rate to activity B. Since activity E never constrains output from activity D, it can also be ignored.

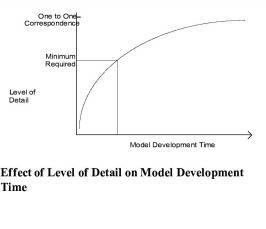

Level of Detail The level of detail defines the depth or resolution of the model. At one extreme, an entire factory can be modeled as a single "black box" operation with a random activity time. At the other extreme, every detailed motion of a machine could be modeled with a one-to-one correspondence depicting the entire machine operation.

Unlike the model scope which affects only the size of the model, the level of detail affects model complexity as well as model size. Determining the appropriate level of detail is an important decision. Too much detail makes it difficult and time consuming to develop a valid model. Too little detail may make the model too unrealistic by excluding critical variables. The following figure illustrates how the time to develop a model is affected by the level of detail. It also highlights the importance of including only enough detail to meet the objectives of the study.

The level of detail is determined largely by the degree of precision required in the output. If only a rough estimate is being sought, it may be sufficient to model each activity by its time, rather than specific details making up the activity. If, on the other hand, details such as downtimes or move times have an appreciable effect on the outcome of the model, they should be included.

Degree of Accuracy The degree of accuracy pertains to the correctness of the data being used. For some models or activities, the information need not be as accurate or exact as it does for others. The required degree of accuracy is determined by the objectives of the study. If the decision is important or a comparison is close, greater accuracy may be required. Accuracy sometimes has to be sacrificed if reliable information is simply unavailable such as when modeling a completely new system.

The required degree of accuracy can have a significant impact on the time and effort required to gather data. It often has little impact, however, on the model building time since a model can be built with estimated values that can later be replaced with more accurate values. Output precision is often governed by the degree of accuracy of the model.

Type of Experimentation The number and nature of the alternative solutions to be evaluated should be planned from the outset in order to ensure that adequate time is allotted. This decision is often influenced by the deadline constraints of the study. Where alternatives with only slight differences are to be evaluated, a base model can be developed requiring only minor modifications to model each alternative. If alternative configurations are significantly different, it may require nearly as much effort modeling each configuration as it does developing the initial model.

For studies in which improvements to an existing system are being considered, it is often helpful and effective to model the current system as well as the proposed system. The basic premise is that you are not ready to make improvements to a system until you understand how the current system operates. Information on the current system is easier to obtain than information on areas of change. Once a model of the current system is built, it is often easier to visualize what changes need to be made for the modified system. Both systems may even be modeled together in the same simulation and made to run side by side. During the final presentation of the results, being able to show both "as is" and "to be" versions of the system effectively demonstrates the impact changes can have on system performance.

Form of Results The form in which the results are to be presented can significantly affect the time and effort involved in the simulation study. If detailed animation or an extensive report is expected, the project can easily stretch on for several weeks after the experimental phase has been completed. Many times the only result required is a simple verification of whether a system is capable of meeting a production requirement. In such cases, a simple answer will suffice.